Circular construction

Circular construction in which materials, whole components, or whole building parts are recycled plays a central role in the transition to a more sustainable use of natural resources.

Construction and production of building materials are estimated to account for 5-12% of the world’s carbon emissions. In the EU, construction waste makes up 35% of the total quantity of waste.

Construction also plays a major part in the consumption of natural resources, using 50% of the materials we recover. Rising urbanization and the growing middle class mean that the world will need to build more than what has been built in the past 4,000 years. This creates pressure on the resources that are stored and exploited in the existing building stock.

A sector development report from DTU concludes that there is a need to set out quality requirements for recycled materials and components, and to develop test methods and training courses to boost circular construction.

The report has been prepared with input from a number of experts and players in the Danish construction industry.

What is circular construction?

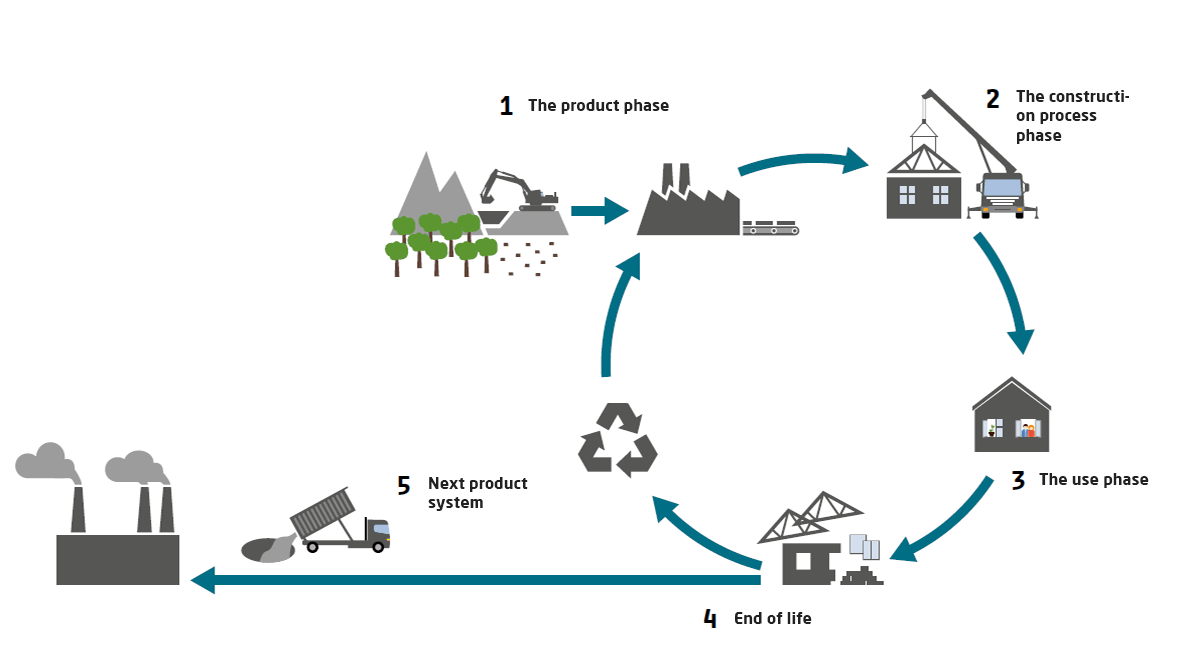

Circular construction is a strategy for the construction sector in which energy consumption and recycling opportunities are crucial in the choice of materials and methods. Reuse is incorporated as an element already before the materials are used for the first time.

The objective of the strategy is to detach the desire for growth from the use of natural resources, thus reducing the overall climate and environmental impacts of society.

The transition to a circular economy is based on three strategies:

- Creating circular resource flows through reuse and recycling.

- Extending the use and recycling phases of the materials through repair, renovation and remanufacturing.

- Reducing the use of natural resources and maximizing the efficiency of production processes.

The transition to a circular economy is highly complex due to the crucial importance of the construction sector to the environment, economy, and social aspects of society. Circular construction entails major changes in the sector. All players in the value chain must be involved, and research, new thinking, and innovation are needed if the transition is really to make itself felt.

The fundamental challenge in circular construction is that economic growth must be made possible while the construction sector uses fewer primary resources. It is therefore necessary to preserve materials and components with the highest possible value for as long as possible. By reusing entire building parts, the construction sector retains the economic values and energy that have been used to process raw materials and manufacture the individual building parts.

How far have we come with circular construction?

An increasing number of architects, engineers, and clients are experimenting with circular construction. They are trying to incorporate from day one the principle that building waste should not end up in landfills or as a filler under motorways, but be used in construction. So far, however, circular construction mostly does not go beyond the pilot project stage.

The transition to circular construction requires a clear and sustained demand that can drive the market. This applies to both building materials and building processes. There are two main reasons for this: firstly the market is new, and secondly the circular principles have not yet been implemented in rules on public procurement procedures, standards, certifications and the Executive Order on Harmful Substances.

In addition, DTU’s sector development report shows that the sector is facing major challenges on the supplier side. The development of a market for a new technology typically depends on both a demand that can drive the development and on a supplier side that is constantly testing new products and processes and gradually drives down the risk, so that more parties on both the demand side and the supplier side take part in developing the market.

On the supplier side in Denmark, this role has currently been undertaken by some small firms of architects. Major firms of architects, developers, and contractors favour the initiative, but medium-sized and large firms of architects are preoccupied with other important agendas.

The sector development report concludes that this is a structural problem concerning development and scaling of circular construction, and that there is a lack of developers of the market on the supplier side that can really boost the development.

Five recommendations for circular construction

The sector development report provides five overall recommendations for a plan for the scaling of circular construction based on five pillars:

- Renovation of existing buildings must be a focal point, but the initiative must also comprise new builds.

- Building materials must be recycled at the highest level, i.e. reuse of the materials that can technically be reused.

- Large and visible effects of the initiatives within all three burning platforms in construction: permanent access to resources, reduction of waste, and reduction of carbon emissions.

- Test projects must comprise testing of new framework conditions within the applicable legislation and the shared technological property and which can form a technical basis for actual scaling of circular construction.

- Denmark must be developed as a Living Lab for the whole world, with an ambition to contribute to meeting international challenges through research and innovation.

Research and innovation

The sector development report also contains recommendations for research and innovation, which are prerequisites for the development of circular construction.

The recommendations comprise the development of methods for documenting the quality of building components with non-destructive tests, which is a research project launched by DTU Civil Engineering with support from Innovation Fund Denmark and Realdania.

In addition, the recommendations focus on developing methods for assessing the environmental impact of construction from cradle to grave, and on generating technical knowledge about recycling and the development of circular processes.

More info

One way of reducing resource consumption is to reuse, recycle, or utilize our existing materials or products. This is called circular economy.

You can read about research projects at DTU that can promote a circular economy and thus help us make our resources last a little longer.

Produced in collaboration with Lisbeth M. Ottosen, professor and head of section for Materials and Durability at DTU Civil Engineering and Mads H. Odgaard, Senior Executive Officer at Office for Research, Advice and Innovation.