Anyone who has boiled water for tea knows that a calcified kettle takes longer and uses more power than a newly cleaned kettle. However, the additional cost to households of using a calcified electric kettle is minimal compared to companies that use calcified heat exchangers.

A heat exchanger is a device that transports heat from one medium to another. For example, district heating plants use them to heat the water that is sent out to Danish homes and buildings. Heat exchangers are also part of the cooling units that manufacturing companies use to cool liquids.

New research from DTU will help calculate the optimal cleaning routines so as to avoid these large and expensive energy losses, while at the same time enabling companies to clean only when necessary.

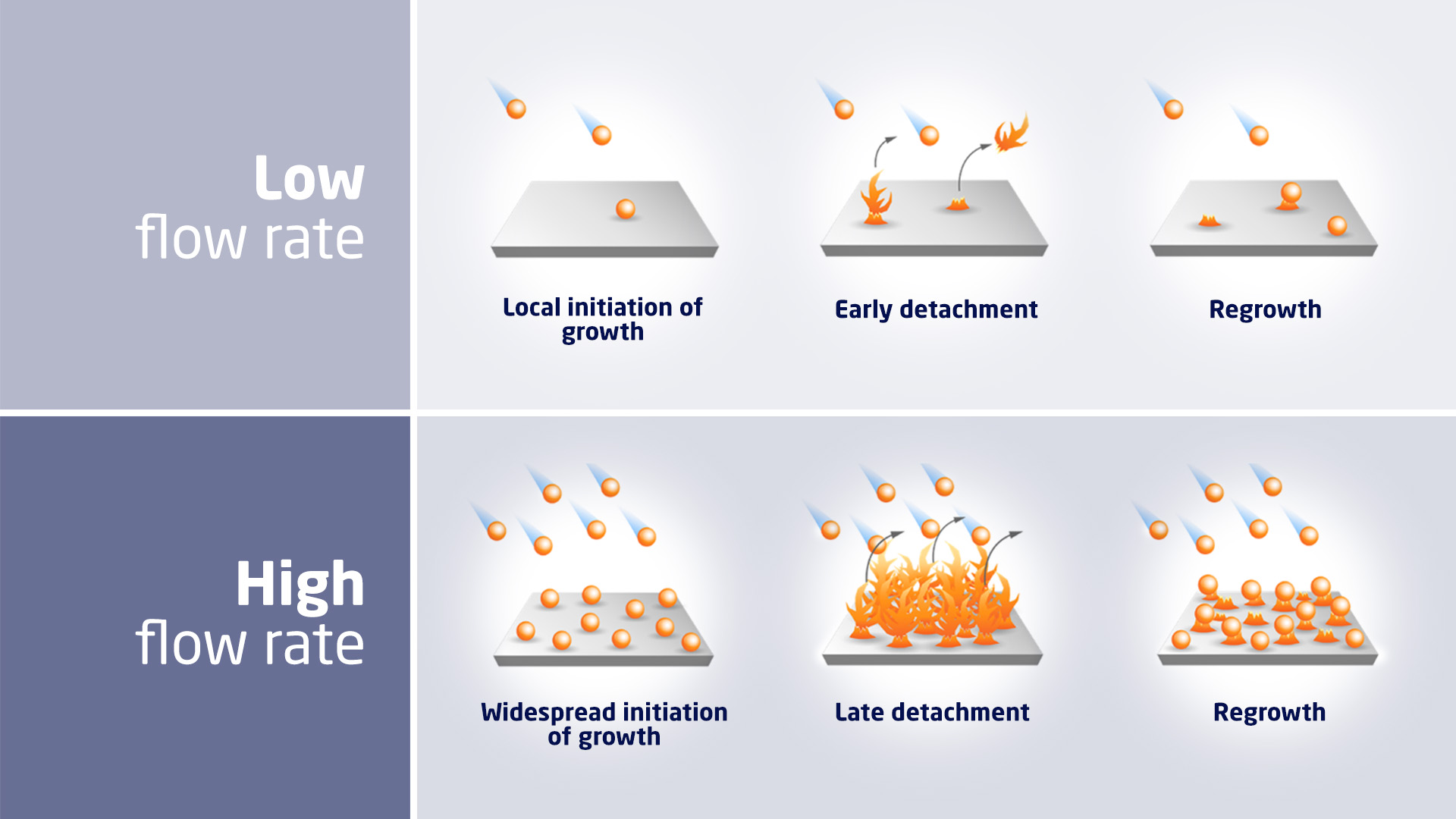

According to Isaac Appelquist Løge, a PhD student at DTU Chemical Engineering, it is possible to achieve significant savings by calculating how quickly a heat exchanger calcifies, so that the accumulation of limescale can be removed at just the right time.

“Calcified surfaces are a much bigger problem than many people think. There are estimates that the cost of maintenance and additional costs from heat exchangers is as high as a quarter of a per cent of the gross domestic product of the industrialized countries,” says Isaac Appelquist Løge.

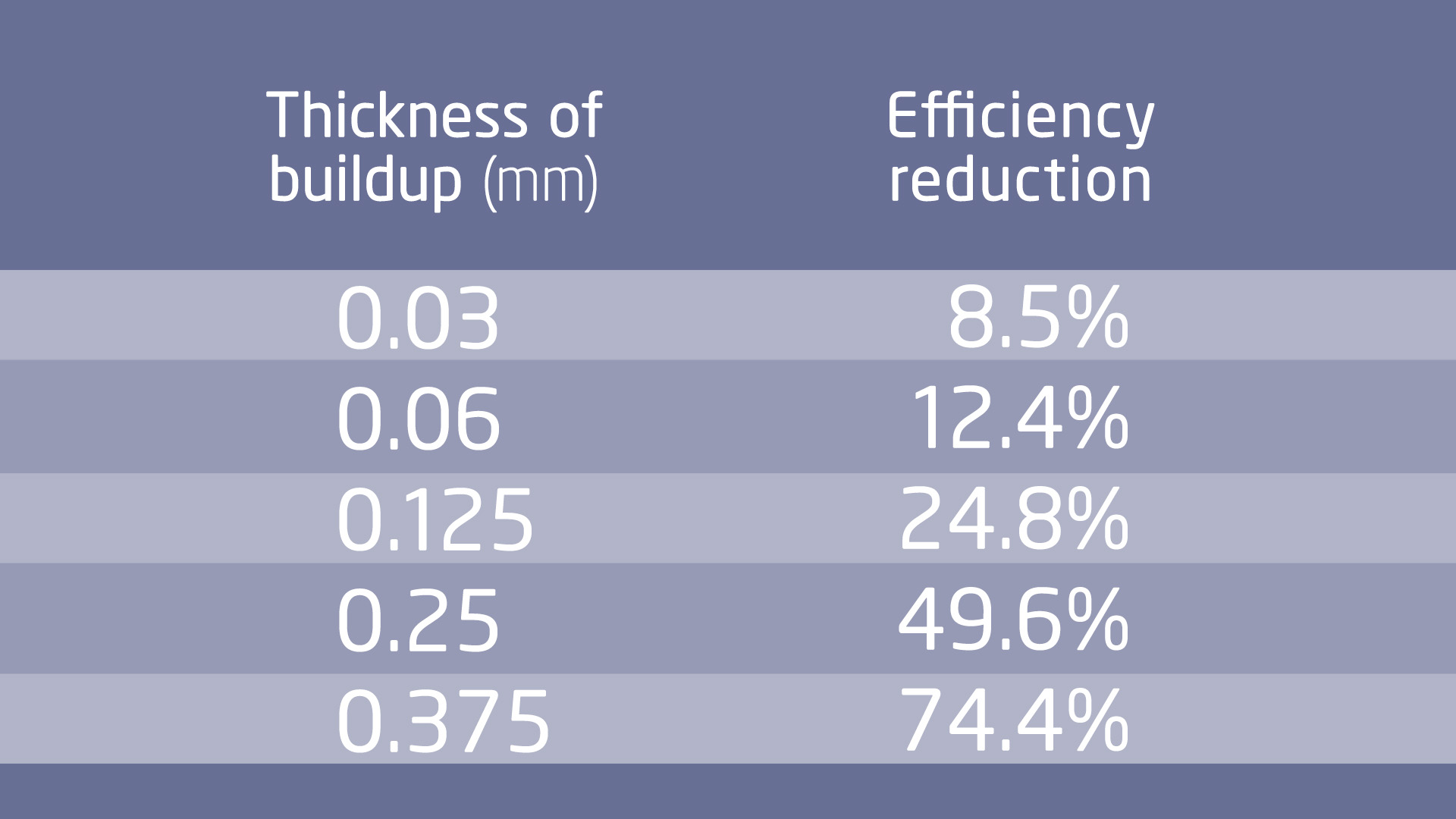

In fact, calculations by the international Association of Water Technologies show that a layer of limescale of 1/8 inch (about 32 mm) causes a 25 per cent efficiency loss. This means that achieving the same heat output costs significantly more. If the limescale accumulation is twice as thick, the efficiency reduction will be twice as big, and the additional cost will also be doubled.